THE INFINITY MIRROR FROM THE NTH DIMENSION

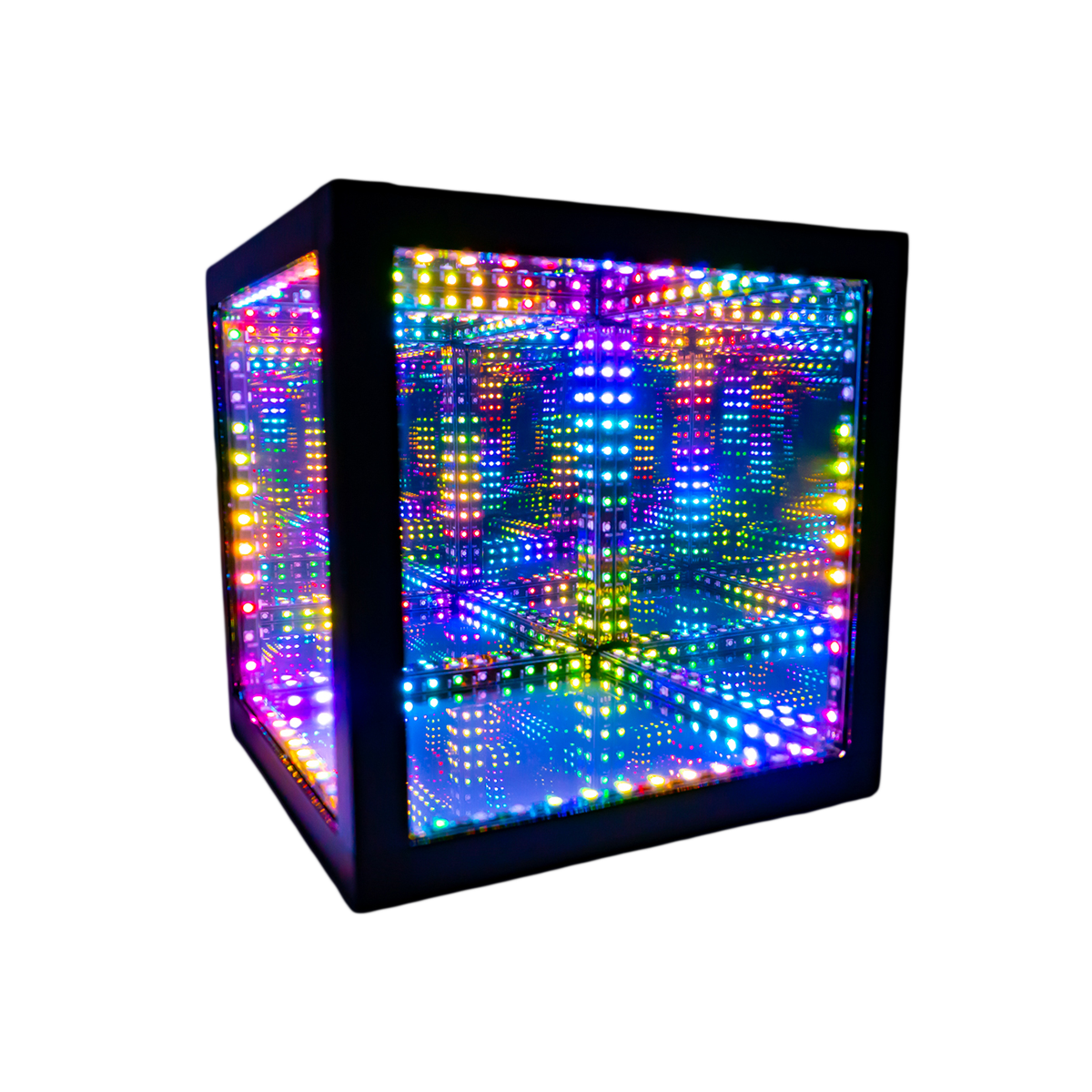

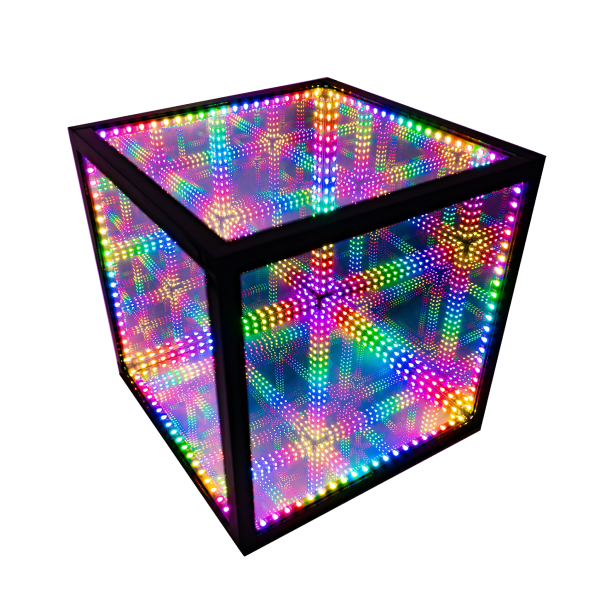

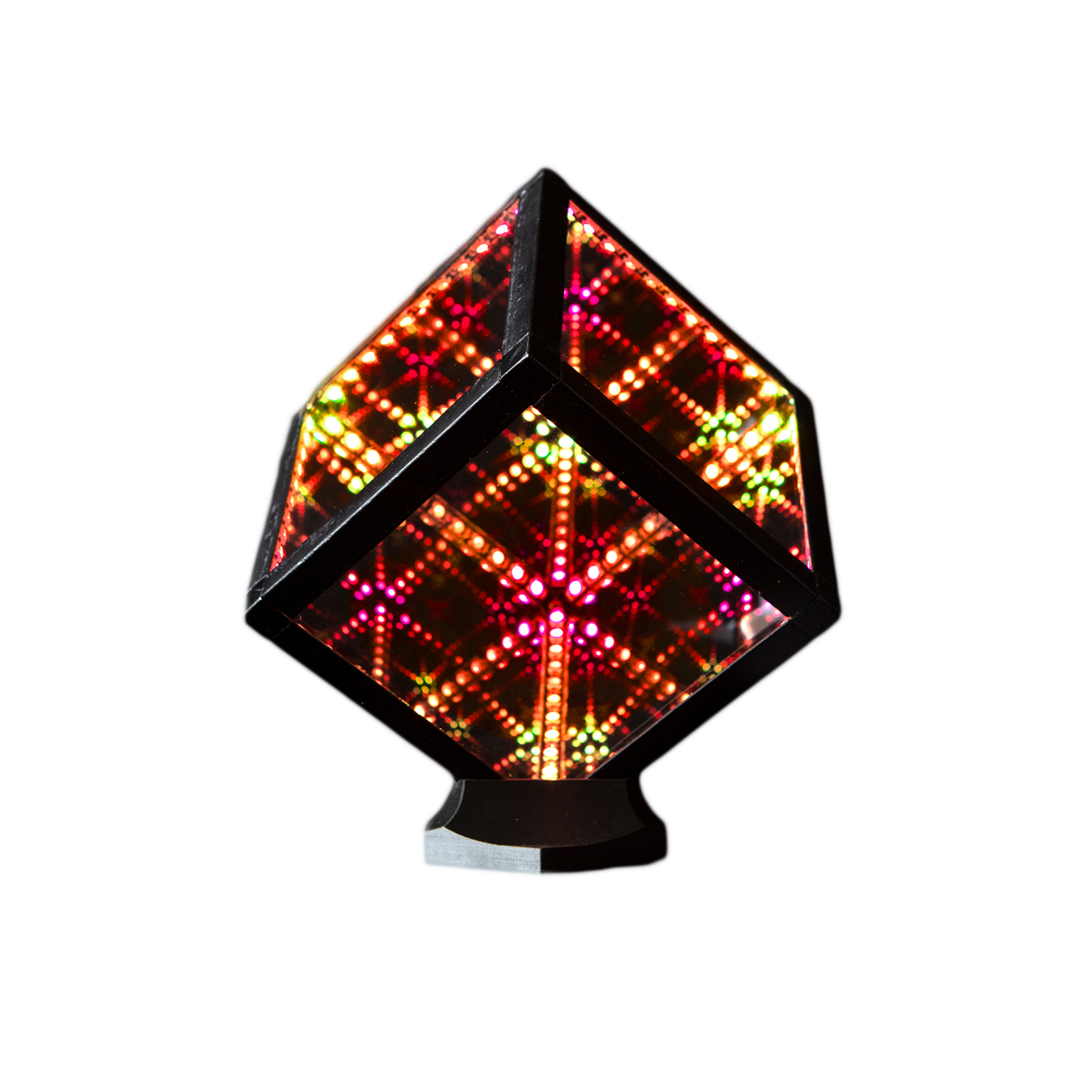

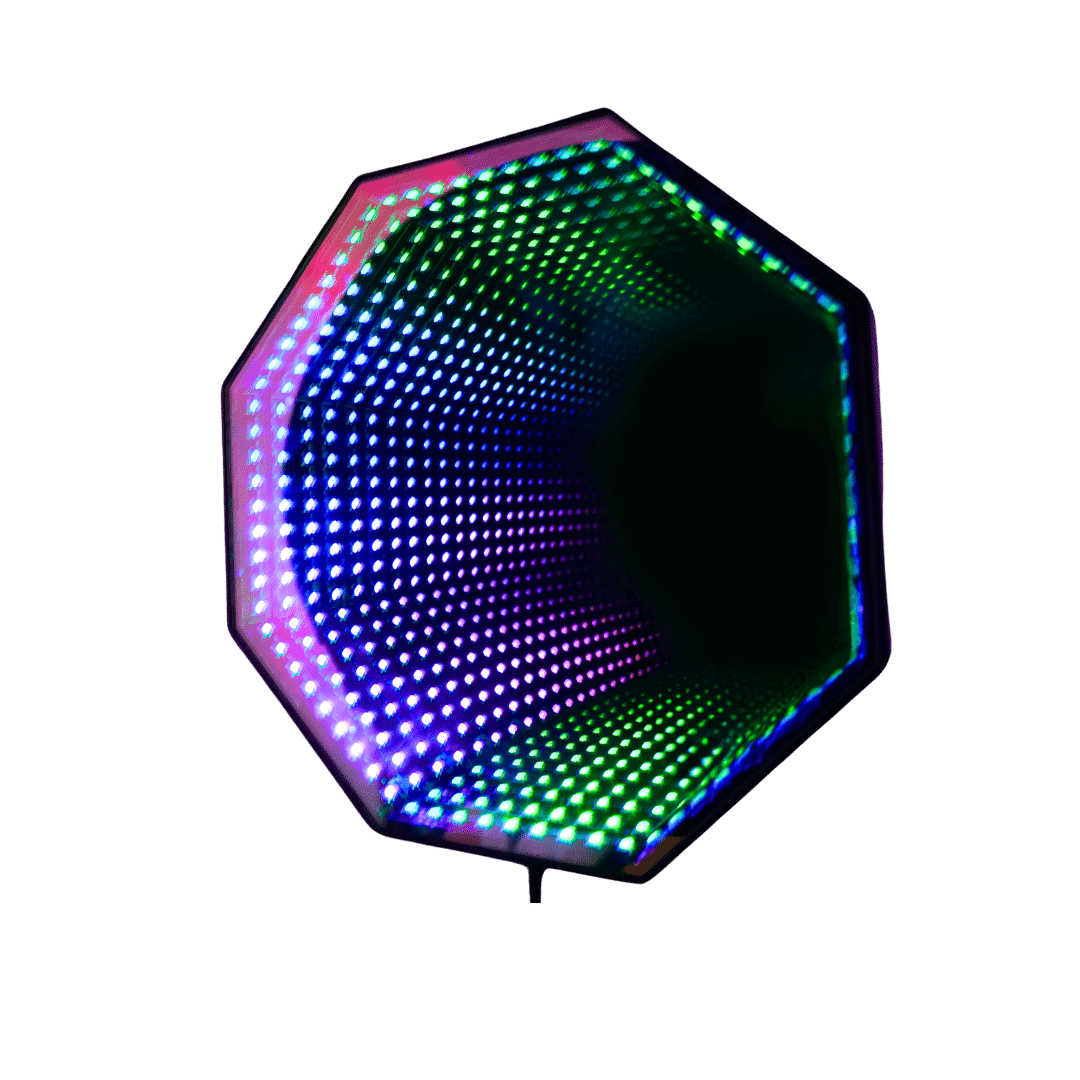

My name is Dylan, hyperspace engineer, Physics Ph.D., artist, burner, and entrepreneur, and this is the history of the Hyperspace Lighting Company. This journey began over two years ago with the video you see above. At that time the HyperCube was nothing more than a personal hobby project, inspired by the art at music festivals and Burning Man, and an attempt to add another dimension to an infinity mirror. Not to mention just a fun way to tinker with electronics and LED art, using creative code to turn math into illuminated art. I had no idea what I had gotten myself into.

This first video of the HyperCube immediately went viral on Facebook, racking up over 1.7M views in the span of a few weeks. I received hundreds of requests from mesmerized humans around the world who wanted one of their own, which is about when TimM and I realized that there was an opportunity to create something grand and magnificent here. Thus, The Hyperspace Lighting Company was born. Our chance to share the beauty of artistic technology and to make the world a little more luminous. Within a month, we launched the HyperCube Kickstarter campaign, which was funded by 543 AMAZING and similarly passionate backers. And the rest, is history! But all that history is why you’re here, so let’s get into it.

We came into the Kickstarter with a whole lot of excitement and passion, and one pre-alpha prototype: something that wasn’t even intended for distribution. Most successful Kickstarter products, on the other hand, start with a design intended for scaled-up production and a few working prototypes, which, in hindsight, is a really, really good idea. But hey, we were capable, confident, and impatient! There’s a dream to build! What followed was an incredible amount of work pulling everything together: building up the business infrastructure and the brand; creating a website; building prototypes; coding the patterns, features, and sound reactivity; designing each of the many components in the cube and the custom controllers; and finding suppliers and manufacturers to produce each of those components. Among countless other little things. To get the quality we wanted, we’d have to vet and test sample work from many sources before making final decisions, for each and every aspect of the project. We had our work cut out for us, but luckily we loved what we were doing. We couldn’t have done it without that passion.

Building A Dream

It’s difficult to describe all the steps that went into the process of building a business and a manufactured product, so for now I’ll just tell the story of one component: the frame. We started with the basics, creating CAD models and 3D printing our first proto designs. At the same time we met a manufacturing partner, Gavin, who could help with sourcing many of the components and with the final assembly. How fortuitous, we thought! There’s so much to be done and we could really use some help. After discussion together, we decided to try a different route with the design using all extruded parts and foregoing expensive and time-consuming injection molding of the frame.

We steadily made progress, iterating the design over and over. Little did we know, prototyping a complex product like this takes a hell of a lot of trial and error and time. A big part of this is the interdependent nature of the whole: when one piece changes even a small amount, it affects the design of the rest, requiring modifications to other pieces. And sometimes there are unforeseen and unintended consequences of design changes, requiring further modification after testing. The kicker is that it takes a few weeks to modify the design, confirm with suppliers, produce the new samples, and ship to us. With all the component modifications, big, small, and unexpected, the time very quickly adds up.

After a few months of this we realized a few things all at once: not all suppliers produce quality parts, the current design wasn’t cutting it, and our initial Kickstarter timelines were unrealistically ambitious. We initially planned to deliver a finished product in August 2019, so we added a couple months to the timeline (that’s all we’ll need, of course), dropped our frame supplier, and hired a professional design firm to help out with the design. We’re engineers, but we’re not experts, especially when it comes to the specifics of injection mold design. Within a few weeks, we had a fresh design and a new supplier, at the suggestion of our design firm, ready to produce samples. Perfect, we’re on a roll! And now we wait… and wait some more… and some more. These parts are produced by injection mold, injecting hot plastic into a cavity and letting it cool. It typically takes a month or maybe two to create that mold according to spec, but we waited nearly five months. It was only after that we realized the supplier put us off to prioritize a customer with a larger order. Red flag #1.

We were excited to finally receive the frame parts after so long, and expected to move into mass production shortly. We had already put money down on some other components. At a glance the new parts looked great, but they had issues. The outer struts snap on to the inner frame, but the latches were not made to spec and required an immense amount of force to attach, making them unusable. So we had to go back and modify the mold. Then our supplier broke the mold in making changes, and we had to wait another month for a new one to be produced. After which the parts required further tuning. This was.. disheartening, to say the least. Perfecting a design is an endless process, but progress was being made even more slowly than usual.

What More Could Go Wrong?

It’s difficult to describe all the steps that went into the process of building a business and a manufactured product, so for now I’ll just tell the story of one component: the frame. We started with the basics, creating CAD models and 3D printing our first proto designs. At the same time we met a manufacturing partner, Gavin, who could help with sourcing many of the components and with the final assembly. How fortuitous, we thought! There’s so much to be done and we could really use some help. After discussion together, we decided to try a different route with the design using all extruded parts and foregoing expensive and time-consuming injection molding of the frame.

We steadily made progress, iterating the design over and over. Little did we know, prototyping a complex product like this takes a hell of a lot of trial and error and time. A big part of this is the interdependent nature of the whole: when one piece changes even a small amount, it affects the design of the rest, requiring modifications to other pieces. And sometimes there are unforeseen and unintended consequences of design changes, requiring further modification after testing. The kicker is that it takes a few weeks to modify the design, confirm with suppliers, produce the new samples, and ship to us. With all the component modifications, big, small, and unexpected, the time very quickly adds up.

After a few months of this we realized a few things all at once: not all suppliers produce quality parts, the current design wasn’t cutting it, and our initial Kickstarter timelines were unrealistically ambitious. We initially planned to deliver a finished product in August 2019, so we added a couple months to the timeline (that’s all we’ll need, of course), dropped our frame supplier, and hired a professional design firm to help out with the design. We’re engineers, but we’re not experts, especially when it comes to the specifics of injection mold design. Within a few weeks, we had a fresh design and a new supplier, at the suggestion of our design firm, ready to produce samples. Perfect, we’re on a roll! And now we wait… and wait some more… and some more. These parts are produced by injection mold, injecting hot plastic into a cavity and letting it cool. It typically takes a month or maybe two to create that mold according to spec, but we waited nearly five months. It was only after that we realized the supplier put us off to prioritize a customer with a larger order. Red flag #1.

We were excited to finally receive the frame parts after so long, and expected to move into mass production shortly. We had already put money down on some other components. At a glance the new parts looked great, but they had issues. The outer struts snap on to the inner frame, but the latches were not made to spec and required an immense amount of force to attach, making them unusable. So we had to go back and modify the mold. Then our supplier broke the mold in making changes, and we had to wait another month for a new one to be produced. After which the parts required further tuning. This was.. disheartening, to say the least. Perfecting a design is an endless process, but progress was being made even more slowly than usual.

Reflecting And Refracting

Clearly we’ve come a long way. Today, we’re producing over 50 HyperCubes per week, and we’ve delivered hundreds of cubes to our initial Kickstarter backers. After all this time, it’s still a little unbelievable. The story I told above was just the trials and tribulations for one of the HyperCube components. While it’s the most egregious example of what went wrong, we had similar landmines to leap over, skirt around, and jump straight into for each and every aspect of the project: for all the other components, for logistics services, for contract work, for our own personal mental health, and on and on. But you know what? I wouldn’t trade it for any other experience. The road to get here was tough, but in going through hardship we learned far more than we would have if it had been smooth flying. The last two years have been the greatest learning experience of our lives. It has shown us just how much work goes into building a business from the ground up, and has given us an extraordinary appreciation for our own accomplishments and those of others.

Alright, if you made it to the end of my long-winded story, you’re probably expecting some words of wisdom or lessons learned. So without further ado, let me impart to you a few nuggets of wisdom if you’re thinking of starting your own business:

- Not everything will go according to plan, and that’s ok. Do everything you can to make it work anyway. Most problems have many solutions.

- Do as much work as you can yourself, but reach out to experts when you reach the limit of your knowledge. You care about your project more than anyone else, and only you will put in the crazy hours and effort to make it succeed.

- Be exceedingly clear and thorough with your communication and work requests. The more detail you can provide, the closer a project will resemble your vision. Take the time to create outlines specifying every last detail, whether its for a photoshoot, a website, or hundreds of pages of product assembly instructions.

- Vet your people. Suppliers, contractors, everyone. It’s hard when starting out because there’s SO much that needs to be done, but take the time to do your due diligence and research the people and companies you’re working with.

I’m sure we’ll make posts in the future with more insight and lessons, but that’s all I’ve got for now. We’re looking forward to the future, to building great new things, creating new designs with infinity mirrors, and so much more. On February 23rd, we’ll be continuing our expansion and taking new pre-orders for the next batch of HyperCubes. See you in hyperspace!

Chromatically,

Dylan Lovinger

The Hyperspace Lighting Company